Applying the Hierarchy of Controls: A Smarter Way to Solve Safety Issues

Guest post from Olivia Bontems, LMCIT loss control consultant

When it comes to workplace safety, it is easy to default to the most visible solution: hand out PPE, post a warning sign, or send out another reminder email. While those steps can help, they are often the least effective way to control hazards. That’s where the Hierarchy of Controls comes in. It’s a smarter, more strategic approach to identifying and addressing safety issues, and it works especially well in municipal operations where employees wear many hats and face a wide range of risks.

What is the Hierarchy of Controls?

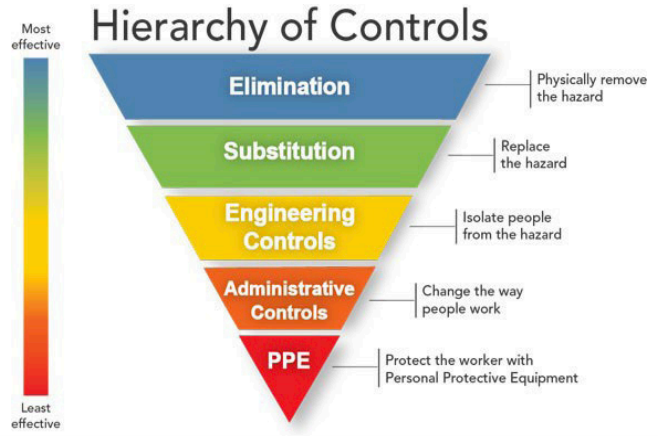

The Hierarchy of Controls was developed by the National Institute for Occupational Safety and Health (NIOSH) to reduce exposure to hazards, ranked from most to least effective:

Elimination – Physically remove the hazard

Substitution – Replace the hazard with something safer

Engineering Controls – Isolate people from the hazard

Administrative Controls – Change how people work

Personal Protective Equipment (PPE) – Protect the worker with proper gear

The goal is to start at the top of the hierarchy and work down, focusing first on solutions that address the root of the hazard instead of just reacting to it. Too often, we jump to the quickest or most visible fix, like issuing PPE or posting warning signs, but those controls rely heavily on individual behavior and consistent compliance. They don’t actually remove the danger from the environment.

This shift in approach moves safety from being reactive to being proactive. It prioritizes long-term, sustainable solutions over short-term patches. While it’s not always possible to eliminate every risk, working through the hierarchy ensures we’ve considered all reasonable options before settling on the least effective ones. In the end, it leads to safer workplaces, fewer incidents, and more confidence among employees that their well-being is being thoughtfully addressed, not just managed.

What Could This Look Like in Your City?

Let’s look at a few examples:

Public Works: Handling a Chemical Product

Hazard: Workers are using a cleaning agent that causes skin irritation

Common Fix: Use gloves and goggles

Better Approach:

Substitute with a safer product that doesn’t require PPE

If that’s not possible, engineer a dilution system or enclosed dispensing unit to reduce exposure

Streets & Parks: Leaf Blower Noise

Hazard: Prolonged exposure to loud equipment

Common Fix: Hearing protection

Better Approaches:

Eliminate by switching to manual tools (e.g., rakes, brooms) in low-traffic areas

Substitute with battery-powered models that run quieter

Add administrative controls like rotating job duties and limiting usage times

City Hall Front Desk: Public Interaction Risk

Hazard: Aggressive visitor behavior

Common Fix: Add signage or rely on employees to manage situations

Better Approaches:

Engineer a physical barrier or panic button

Adjust administrative policies for visitor protocols and incident response

Why It Matters

Using the hierarchy helps cities:

Solve safety issues more permanently

Reduce liability and long-term costs

Show employees that safety is more than just a checklist—it’s a process

It also helps cities comply with OSHA’s General Duty Clause, which requires employers to provide a workplace free from recognized hazards.

Not every hazard can be eliminated. But working through the hierarchy, starting from the top, forces us to ask better questions and find better answers. It shifts the mindset from “What gear do we need?” to “Why is this risk here in the first place?”

View more OSHA-provided information on the hierarchy of controls.